Hexagon

About Hexagon Manufacturing Intelligence.

Hexagon’s Manufacturing Intelligence division provides solutions that utilise data from design and engineering, production and metrology to make manufacturing smarter. For more information, visit hexagonmi.com.

While specific industries have their own unique challenges and motivations, productivity is central to manufacturing success across the board. Today, continuously improving productivity is essential for competitive success. Hexagon manufacturing technology enables manufacturers to take control of quality at all the key stages of their process. Through an unparalleled portfolio of digital manufacturing technologies spanning CAE solutions for design and engineering, CAD CAM and complementary software for production applications, metrology hardware and software solutions, as well as data management and analytics tools, we empower technology users throughout the process with deep and actionable insight into product quality, ensuring that quality drives productivity.

See What We Do in Your Area of Manufacturing

Metrology

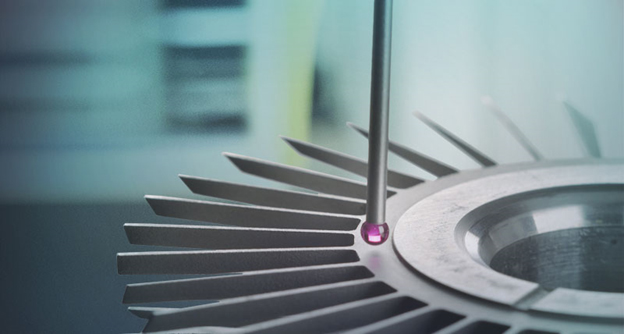

Capture real-world quality data for measurement, positioning and inspection, and use actionable information gained by analysing the results to improve manufacturing processes.

Hexagon Manufacturing Intelligence’s metrology hardware captures quality data for measurement, positioning and inspection. It is the key bridge between the real and virtual worlds, bringing real-world data into the digital domain. Our technology is helping manufacturers to pioneer mechanisms for utilising this data more effectively – using it to inform design and engineering processes and provide feedback to the production process. Our measurement-assisted production technology is best-in-class, and we continue to innovate towards more real-time feedback loop applications.

Role of metrology within the manufacturing process has long been associated with quality assurance – a post-production inspection of the dimensional measurements of a part against specifications. Results either indicated that the the part was either good to go, or that it was not to standard and needed, at best, reworking, or at worst, to be scrapped completely. Metrology was the necessary evil; quality the barrier to productivity.

Hexagon has a proud heritage in metrology, delivering accuracy and precision from the quality room to the shop-floor. Our research and development team is committed to developing new measurement hardware across a technology portfolio encompassing hand tools, coordinate measuring machines (CMMs), portable measuring arms, laser trackers and 3D optical scanners, as well as metrology software and statistical process control (SPC) solutions. We are driving quality inspection technology trends: from contact to non-contact; from offline to integrated; from manual to automated. And, by using our metrology hardware and software solutions in parallel with manufacturing information technologies from the wider product lifecycle, we are driving new definitions of metrology and the quality department, and developing processes where quality drives productivity.

Have Questions About Hexagon ?

GDS Middle East is a leading partner for Hexagon in UAE and Saudi Arabia. We have sales & technical support offices in UAE and Saudi Arabia.

If you are looking for a Hexagon license or training, take the next step. Get in touch with GDS Middle East today.